Introduction

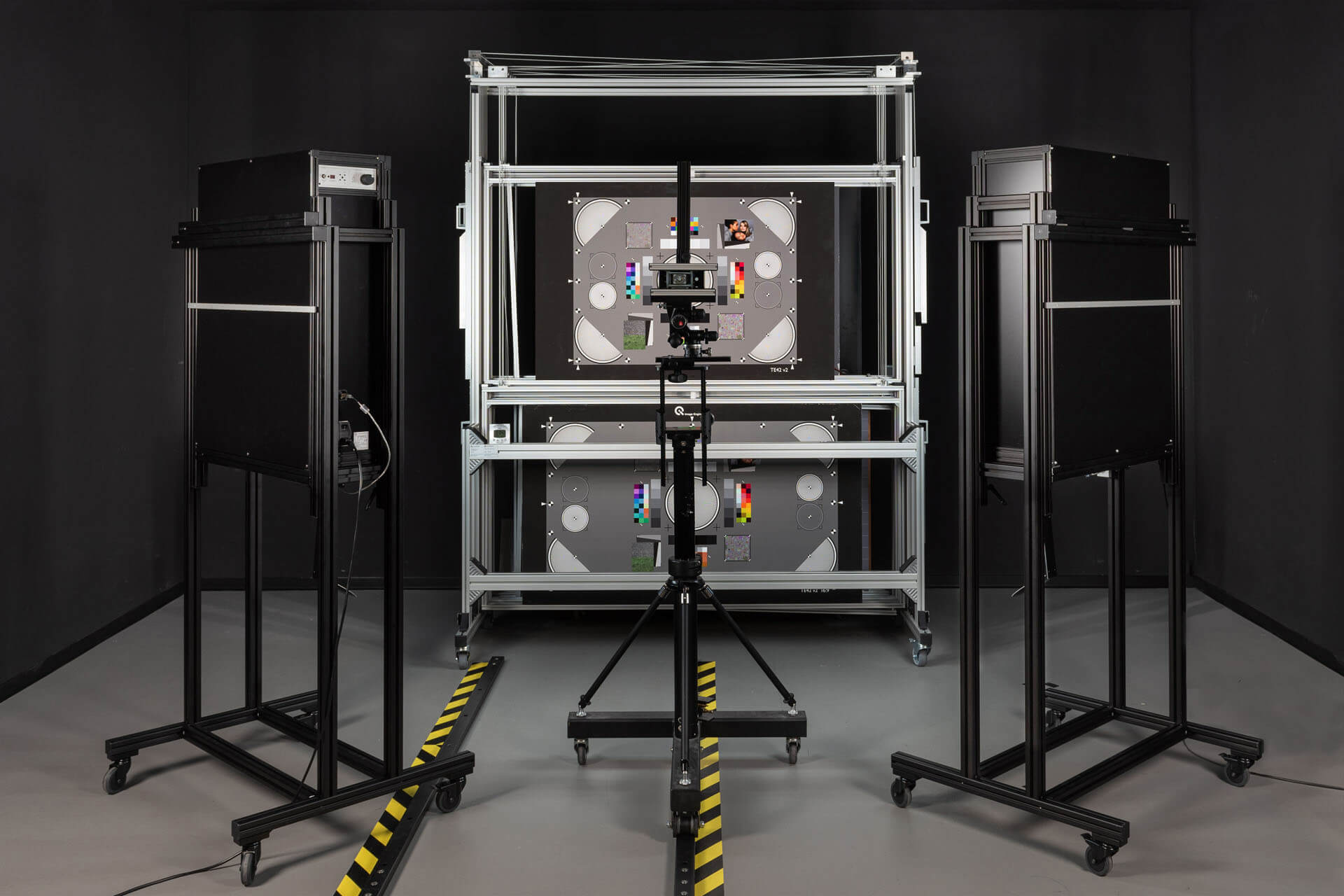

Testing the image quality performance of a digital camera system has changed considerably over the years and continues to evolve and advance as more and more companies and industries utilize camera and sensor systems in their products. In the early years, digital camera testing was traditionally performed in a test lab with a stationary test chart and light source. Each camera is then physically placed in front of the chart for testing. While still widely used and accepted, these methods are limited in scope.

Today, advancing testing technology has provided automated end-of-line characterization and calibration solutions. Automation has become an invaluable resource for end-of-line camera testing, especially when calibrating numerous camera modules on a production line. Without automation technology on a production line, camera calibration and characterization must be done using traditional methods, thus reducing efficiency and prolonging the overall production time.

Automation technology is not just for production lines and can also be utilized in a test lab. Automating a test lab setup will improve efficiency by eliminating the human error often seen in traditional camera testing methods. An automated test lab setup can automatically align a camera system to the test target, instantly transfer images to your PC for evaluation, and manage multiple hardware setups. These features will significantly improve the overall camera testing accuracy.

Automation test requirements

A testing solution must be able to automate lighting, camera positioning, and analysis to be considered a fully automated test process. Building such a solution, especially on a production line, is challenging and requires experts in this area. Image Engineering works with many highly experienced companies in automating the test process, i.e., building the end-of-line testing machine using individual components from other companies. However, these companies often lack the background in the specific tests vital for camera calibration and characterization and thus need assistance in choosing the right components for the end-of-line test solution.

There are many different factors that a camera system must be tested or calibrated for during end-of-line testing to ensure high quality and performance. It is crucial to understand these factors when building an automated test solution because they often require various illumination levels, positioning capabilities, and analysis options depending on the factor.

Image Engineering works with companies to ensure they test the relevant image quality factors. It is also important to note that each industry utilizing cameras will have different requirements; thus, there is no one-size-fits-all solution for end-of-line testing. However, there are a few factors that most companies test for, especially on a production line. These include defect pixels, shading, spatial frequency response, and color calibration.

Defect Pixel, Particles, and Blemishes

Defective pixels, particles, or blemishes can be characterized as unwanted artifacts in an image. Typically, a defective pixel is one or more bright, dark, or colored spots appearing unnaturally in the image. Strong image noise also usually indicates defective pixels. Testing a camera system for defective pixels, particles, and blemishes is vital during end-of-line testing as it can significantly affect the camera's overall image quality.

![]()

Shading

Shading, also known as vignetting or relative illumination, describes the light fall-off or color variation from the sensor center to the corners. In other words, shading decreases the image brightness from the center to the corners. Occasionally a variation of color over the imaging field can occur, particularly in cameras with a small sensor. Shading influences image quality by creating unwanted dark or shaded edges.

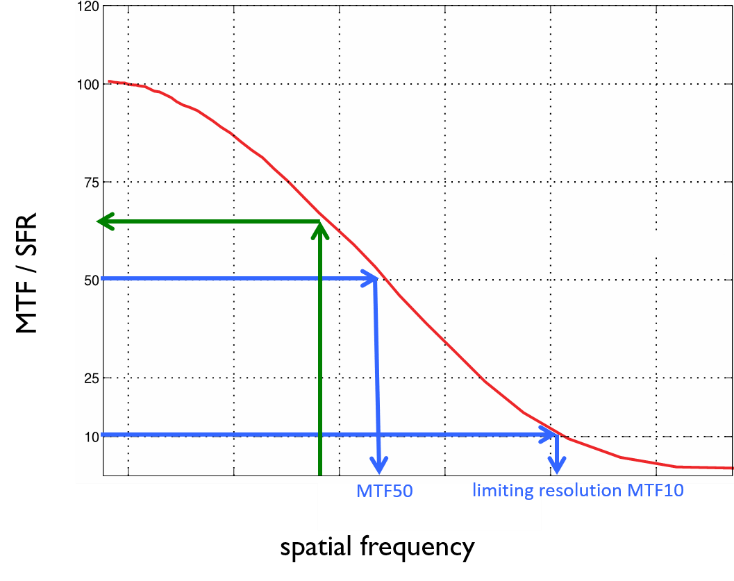

Spatial Frequency Response (SFR)

Camera resolution is one of the most crucial factors for image quality testing, and the spatial frequency response (SFR) is the metric used when describing resolution performance. SFR describes how well the system under test can reproduce a range of spatial frequencies on a scale from 0% (complete loss of information) to 100% (perfect reproduction without data loss). This information is vital for end-of-line testing when determining camera performance.

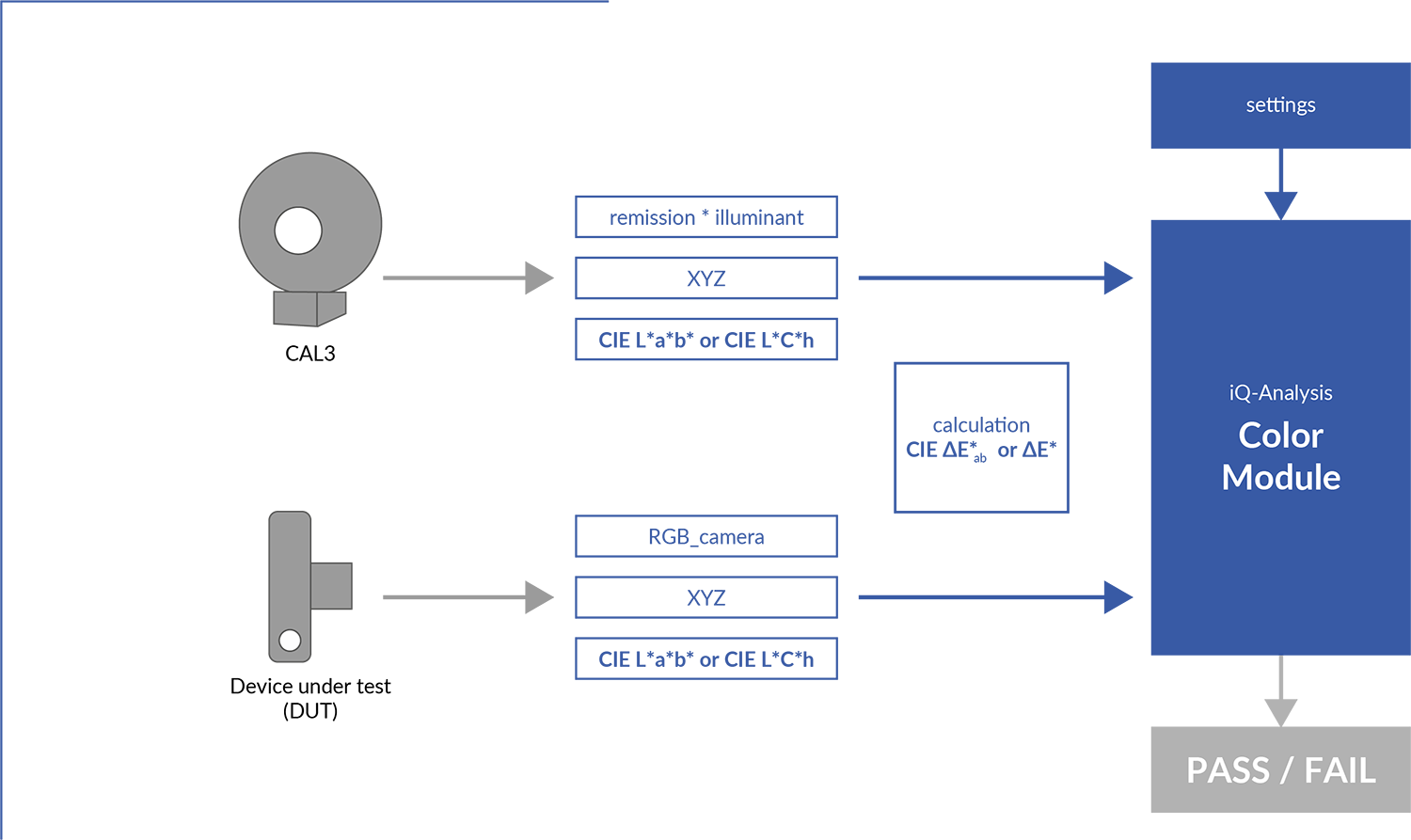

Color calibration

Proper color calibration is vital for camera performance. During production, sensor sensitivity variations may affect a camera system's color accuracy, and the color quality may fluctuate from camera module to module without proper color calibration. Color calibration is essential when testing multiple camera modules on a production line.

Each of these factors (and often many others) must be accounted for when developing an automated end-of-line testing solution that includes illumination, camera positioning, and analysis. Image Engineering offers components for each category to help build an automated end-of-line test solution.

Illumination options

Traditionally, finding correct illumination for image quality testing required multiple light sources with various intensities and spectrums. This challenge has proven difficult for an automated end-of-line test on a production line where camera modules often need to be tested at various spectrums and intensities. iQ-LED technology, developed by Image Engineering, helps solve this problem with a spectrally tunable all-in-one light source that can generate custom spectra.

This light source is easily customizable and can be built into an existing production line for end-of-line testing. You can automate the light intensity and spectrum using the iQ-LED API, giving you complete control over the illumination during testing. We offer many products designed specifically for production line integration using iQ-LED technology.

CAL series

Each CAL product is uniquely designed using a non-reflecting special diffuser filter to ensure even light distribution on the measuring plane. So, as long as the image processing and transfer of the camera are fast enough, a full camera calibration can be completed in a matter of seconds. This capability makes the CAL products ideal for calibrating cameras on production lines.

CAL2

The CAL2 is our most popular device for production line integration, and its edge box design makes it particularly suited for calibrating cameras on a production line. The CAL2 and the accompanying iQ-LED software can substitute for multiple illumination devices on a production line, making mass camera calibration and characterization far more efficient.

Positioning options

Automating camera positioning can also prove challenging on a production line or in a test lab. We do not develop end-of-line test machines, but, as mentioned above, we work with experts in that field to ensure they understand the camera test requirements. However, we offer a few automated test solutions for a test lab.

iQ-Automator Solution

The iQ-Automator is software designed to automate basic image quality tests in a test lab. Initially developed for mobile phone testing, the iQ-Automator can also be adapted for cameras from other industries (not all camera types are currently possible). The software is combined with a robot arm to complete the solution. With six degrees of freedom, the robot arm can automatically position a camera for testing. Using automation for camera positioning in a test lab considerably reduces human error and increases the accuracy of the test results.

Analysis options

The final part of a fully automated test solution is an analysis of the test results. On a production line, our partners handle the construction of the complete end-of-line testing machine, but once the test images are captured, we handle the image analysis. Until recently, image quality evaluation was done as a separate step in the test process, taking much more time for a complete camera analysis. This challenge was particularly a problem on production lines when the results from each module had to be evaluated separately. In 2021, we introduced the iQ-Analyzer-X analysis software to optimize and automate image quality evaluations.

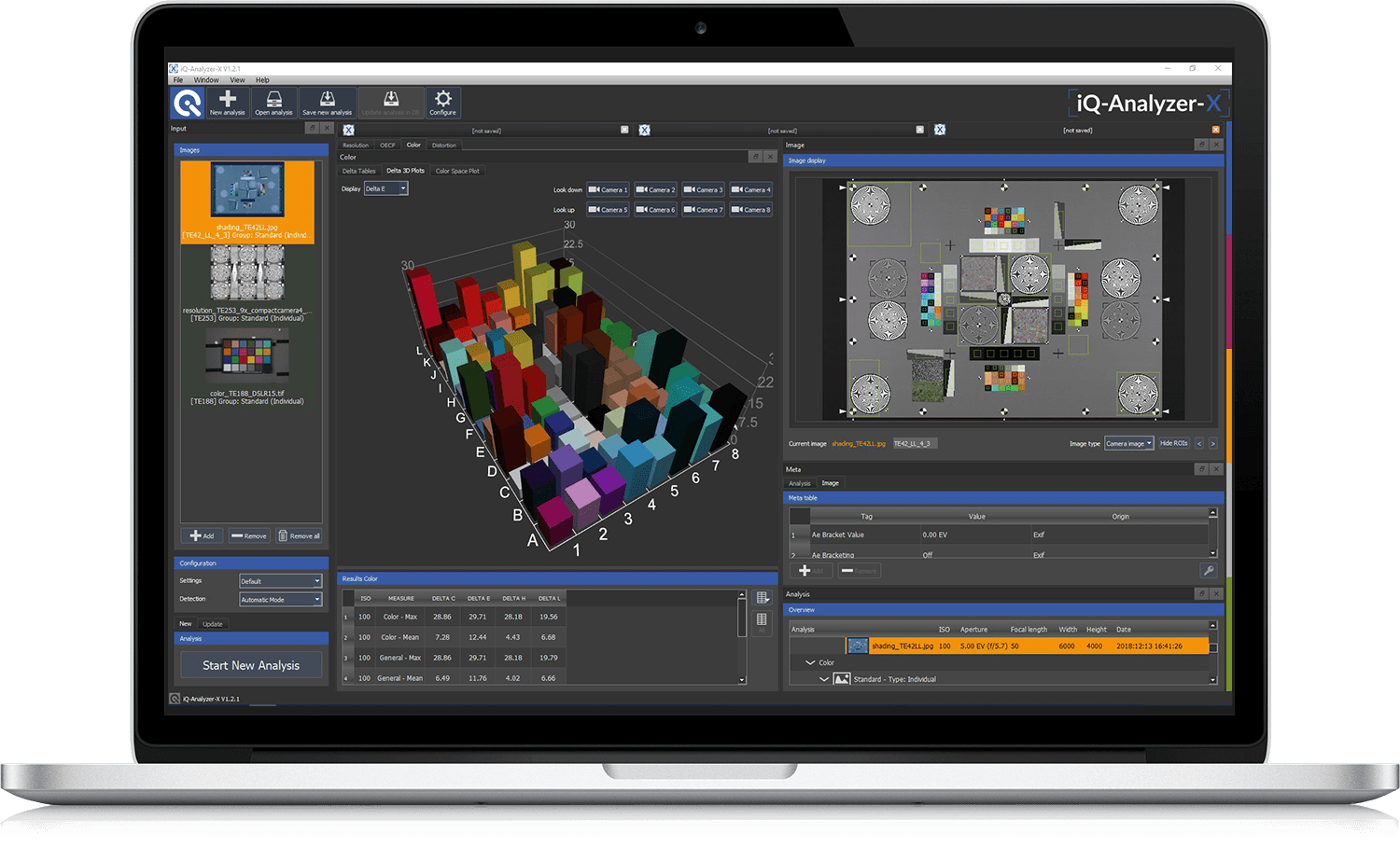

iQ-Analyzer-X

iQ-Analyzer-X introduces the next generation of image quality analysis. As more and more companies look to automate their end-of-line testing completely, it was only natural to refine our iQ-Analyzer software to meet the growing automation requirements.

iQ-Analyzer-X is a versatile software built entirely on C++, giving us a more modern approach to image quality evaluation. Core features include automatic chart detection and saving test results directly into a local or external database. Another important feature for automating your testing is the use of hot folders. Hot folders allow you to create folders with different test settings. Once images are added to one of these folders, the software will automatically analyze the images based on the settings of the hot folder.

The iQ-Analyzer-X also includes a command line feature for automated testing. This feature allows you to create a sample batch file with custom settings for analysis. These batch files give you a starting point for creating your own tools directly into the interface of the iQ-Analyzer-X. All these features allow the software to be incorporated into end-of-line testing without human interaction. We have already seen many companies benefit from using iQ-Analyzer-X on their production lines.

VIDEO

iQ-Image Analysis API

As more companies begin to automate their end-of-line testing, we recognize that each one typically has different requirements, and the standard iQ-Analyzer-X may not fit those needs. The iQ-Image Analysis API provides a solution for integrating the analysis software into individual workflows for specific tasks.

This API can accommodate individual pass/fail thresholds for automating end-of-line testing. It can be used to create custom measurement modules that meet individual evaluation specifications (e.g., pass/fail thresholds). Using available modules as the API foundation allows us to add the desired specifications to provide a custom solution.

The API is developed for deep integration into a workflow giving you complete control over the code and data flow of the end-of-line camera evaluations. Contact us for more information on customizing the iQ-Image Analysis API for your workflow and evaluation requirements.

Conclusion

Automation has become an invaluable resource for end-of-line camera testing, especially when calibrating numerous camera modules on a production line or in an automated test lab. Without automation technology on a production line or test lab, camera calibration and characterization must be done using traditional methods, reducing efficiency and prolonging the overall production time.

Building an automated test machine for end-of-line testing requires experts in this field. However, these experts often lack the knowledge on what needs to be tested during these end-of-line tests and thus may not fully optimize the machine. An automated camera testing process requires illumination, camera positioning, and analysis. At Image Engineering, we work with these companies and provide the testing expertise and many illumination and positioning components to fully maximize the efficiency of a complete automated end-of-line testing solution.

Whether optimizing your production line calibration and characterization or fully automating your test lab, we can help you find the right solutions to improve efficiency and reduce overall production times.