Automotive Testing

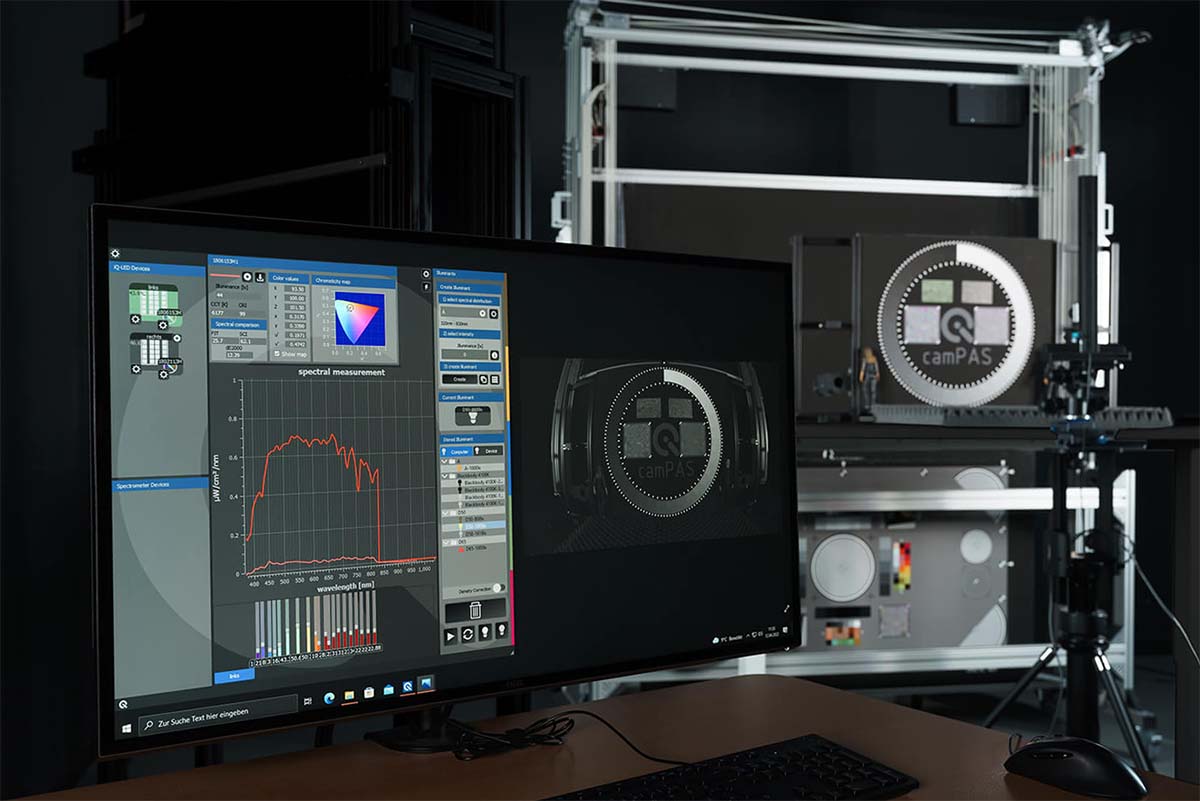

The camPAS (Camera Performance for Automotive Systems) test is a uniquely designed image quality performance test for camera image quality and sensor systems (e.g., the smoothness or error susceptibility of the sensor) within the automotive industry. We offer camPAS to clients who need independent and objective test results from a neutral third party to support their development decisions.

The IEEE-P2020 working group has published an image quality test standard for automotive camera systems in early 2025. At present, P2020 is the only industry-wide test standard. Developing the camPAS test resulted from assisting our clients in searching for and creating test methods that provide unbiased results. As an active member of IEEE-P2020, we can implement the latest automotive camera test methods and procedures from the standard directly, keeping camPAS relevant and up-to-date.

Who can benefit from using camPAS?

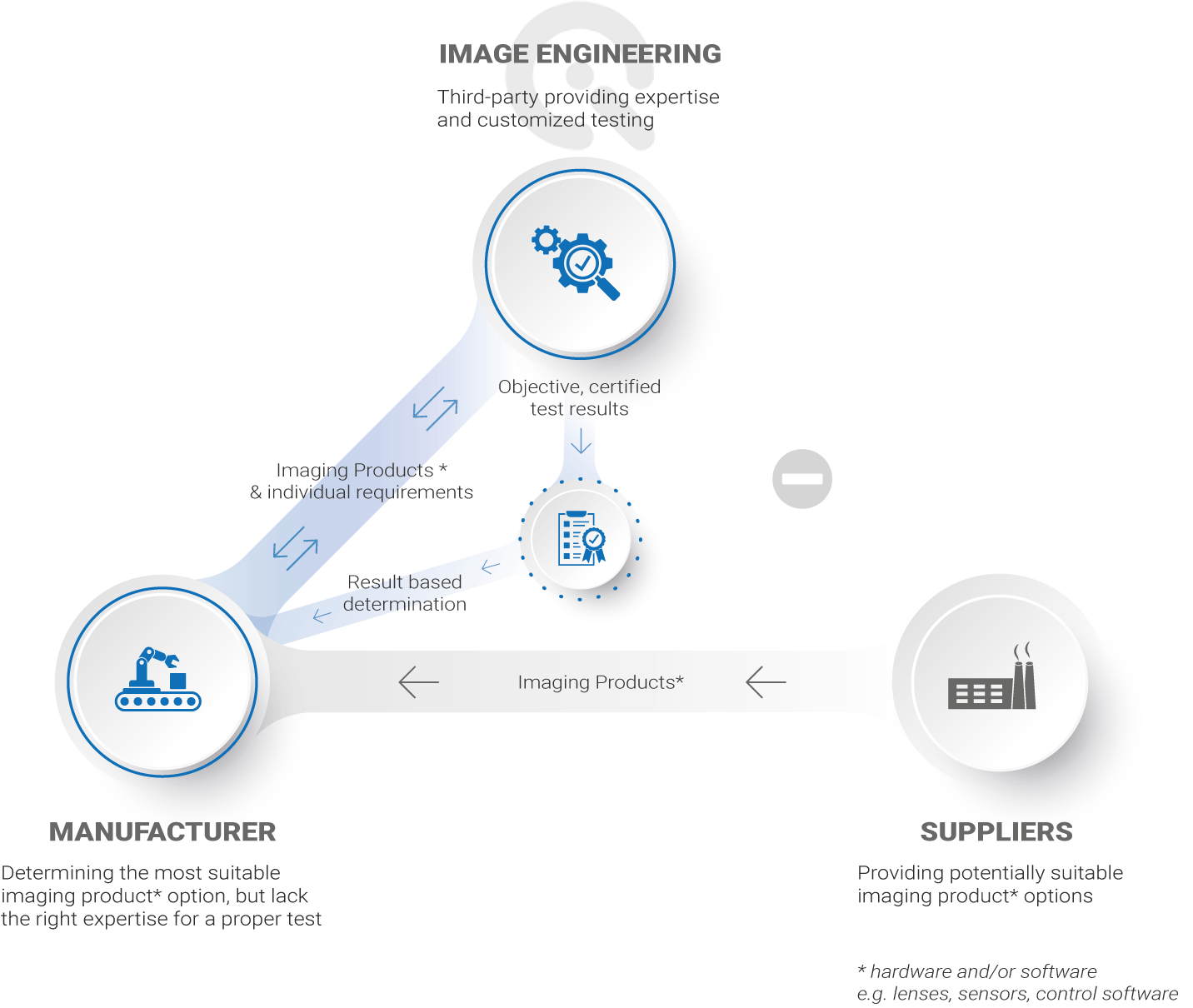

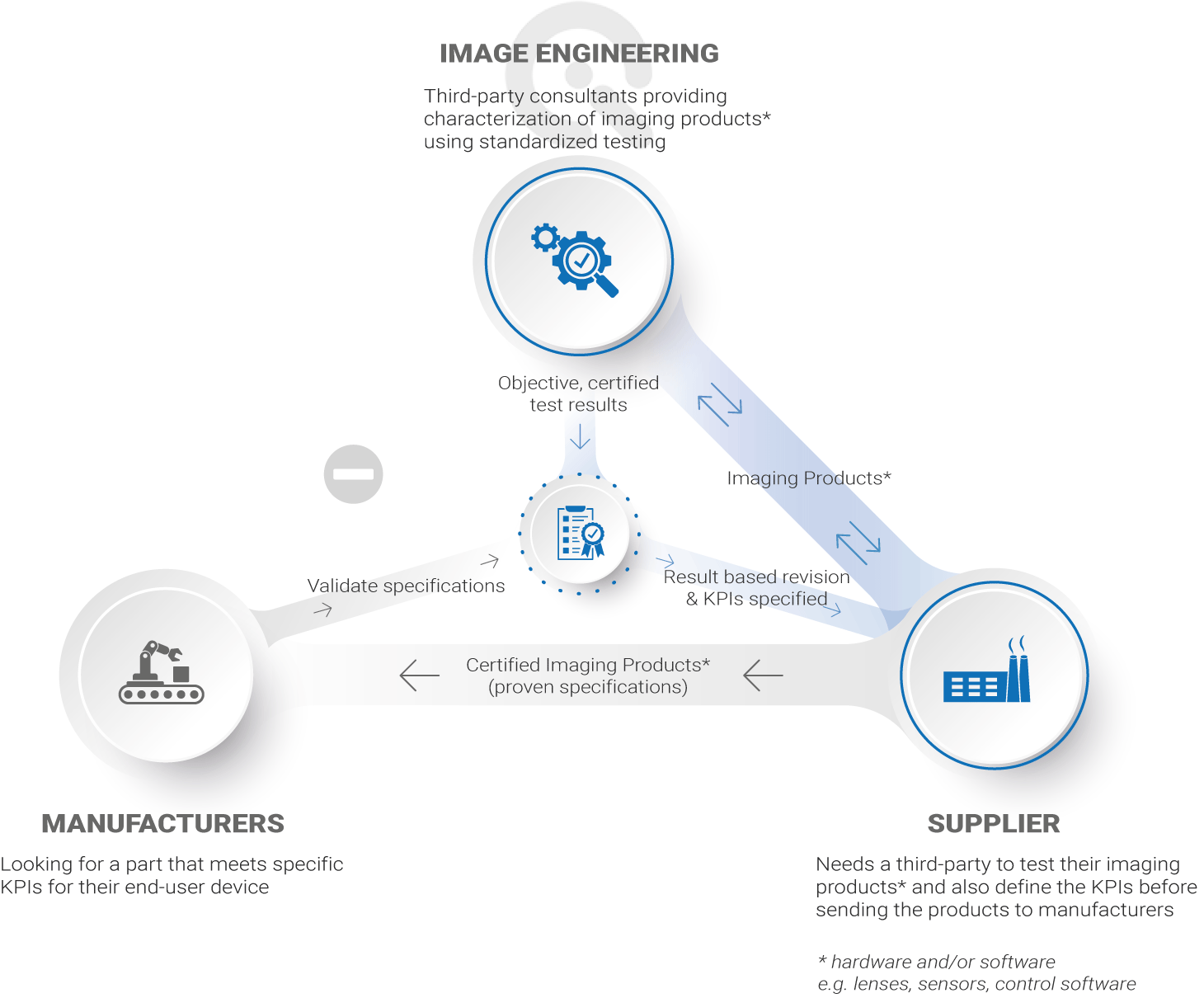

camPAS is developed as a third-party solution for end device manufacturers and component suppliers. We provide objective test results based on a custom test agreement between the manufacturer or supplier and us, acting as the third-party tester. The results are kept confidential between Image Engineering and the customer if desired.

Manufacturers

The manufacturer in this situation will benefit from the expertise and customized testing that Image Engineering offers as a third party. The objective tests can assist the manufacturer in finding the most suitable sensor (from a wide range of available sensors) for their requirements.

We work with them to create a customized camPAS test using their specifications and perform the test. Our engineers will then provide objective results for the manufacturer to make a more informed decision.

Suppliers

The supplier in this scenario can also benefit from using Image Engineering as a third-party neutral consultant. Before the supplier releases their devices to the end-user manufacturer, they can send them to Image Engineering to validate them using a camPAS test. We also use camPAS tests during the sensor development stage so the supplier can develop a sensor using third-party recommendations.

After completing a camPAS test, our engineers will point out potential image quality improvements. We can also often detect bugs, errors, and other problems the supplier can improve on before they provide their devices to the manufacturer. We can use these tests to define relevant KPIs accurately and inform the supplier of their devices' capabilities. Finally, the supplier can use the results to prove that the hardware meets the manufacturer's requirements.

What tests are included in camPAS?

The difference between a camPAS test and a standard test method is the ability to customize the camPAS test entirely depending on the client's specifications. We evaluate camera systems using various image quality KPIs or utilize tests to analyze the smoothness or error susceptibility of the sensor.

A few of the most common image quality KPIs that we test for include contrast transfer accuracy (CTA)*, modulated light mitigation probability (flicker), high dynamic range (HDR), visual assessment of the low-light performance, etc. These tests are performed using the latest techniques (such as those outlined in IEEE P2020) and equipment to ensure the highest results.

It's important to note that these KPIs are only examples, and we test an extensive range of KPIs for both camera and sensor systems. camPAS tests are not ready-made tests and instead require a consultation with our test lab to ensure that we design a test to fit the client's requirements.

Contact our test lab to schedule a consultation on getting started with a camPAS test.

*In the latest revisions of the IEEE-P2020 standard, the term contrast transfer accuracy (CTA) has replaced contrast detection probability (CDP).However, CDP will still regularly appear in papers and documentation from the past few years.