Production Line Integration

TechnologyIntroduction

Optimizing camera calibration and characterization on a production line is often a challenge for camera manufacturers as integrating traditional light sources (e.g., fluorescent or simple LEDs) will often cause issues with stability and repeatability. Another problem for production line calibration is how to generate the variety of lighting scenarios that the camera may encounter in the real-world.

A proper test protocol will use a variety of testing scenarios and light spectra to ensure all aspects are characterized before the device is in the consumers hands. Without the ability to test multiple scenarios, a device under test risks receiving a “pass” when in reality it has only passed production line standards and not necessarily real-world standards.

With these problems in mind, our R&D department set out to create the unique iQ-LED technology with the intent to make this technology available for production lines in the form of integrating spheres. These integrating spheres combine iQ-LED technology to create a series of “CAL” devices that are easy to implement into a production line.

An overview of iQ-LED technology

iQ-LED technology has the ability to generate custom spectra in a controlled lab environment. The ability to replicate other light sources makes this technology a powerful tool for manufacturers that need to test their cameras in various light situations. This ability is particularly relevant for production lines as you only need to implement one light source into the workflow.

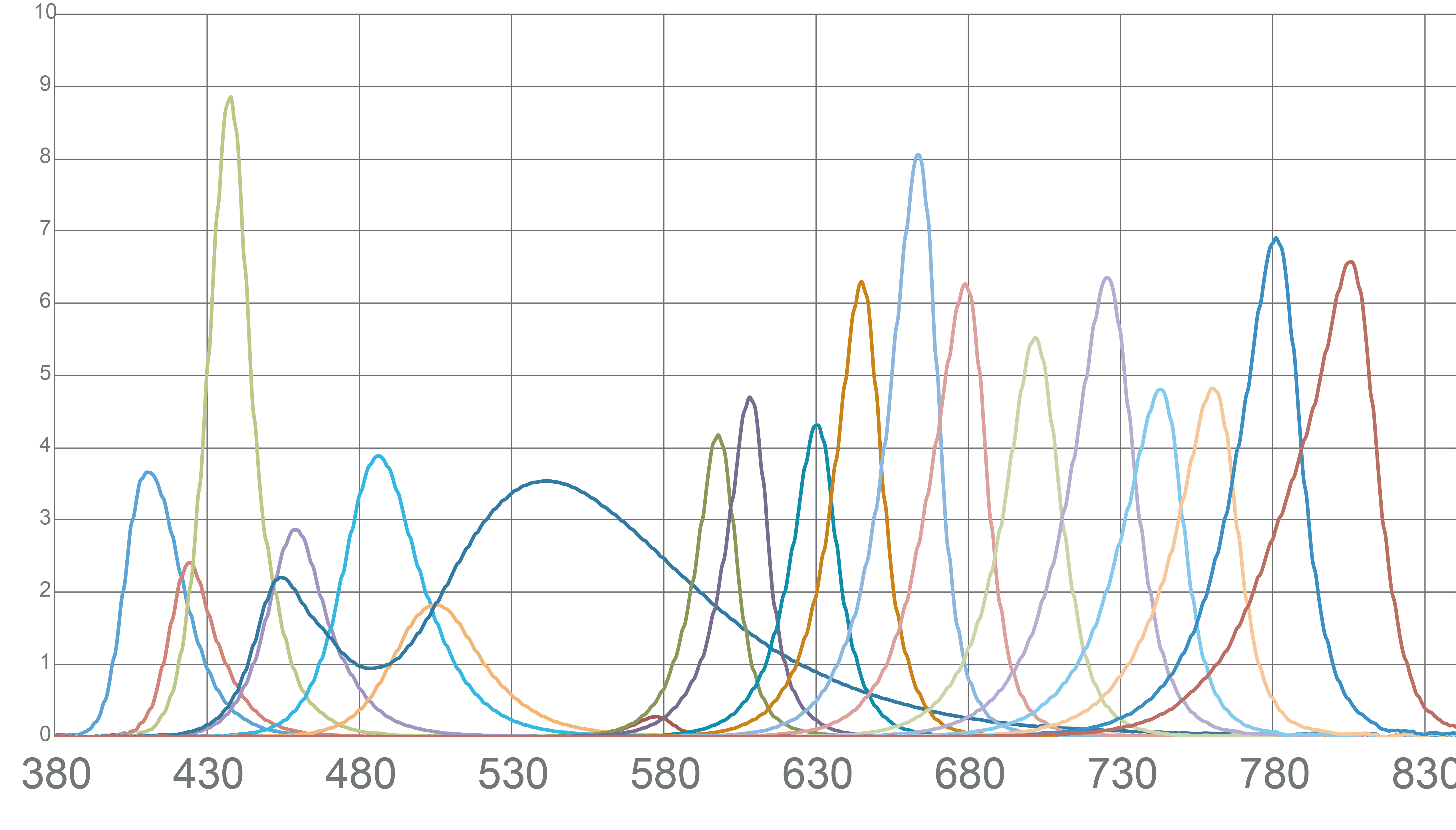

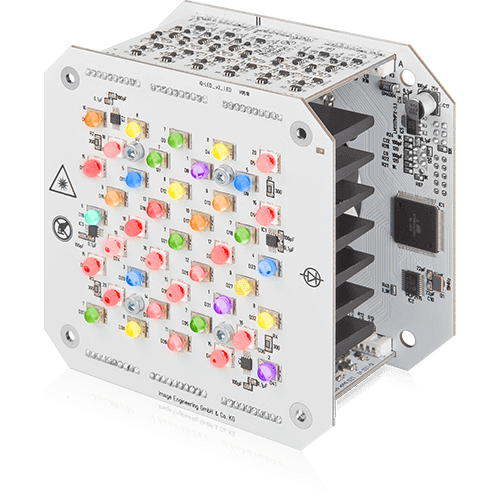

iQ-LED technology can generate custom spectra by the optical mixing of emitted radiation from spectrally different LEDs. We harness the technology through the use of standard modules that each consist of 20 different channels generated from 41 high-power SMD LEDs on a 10 x 10 cm board.

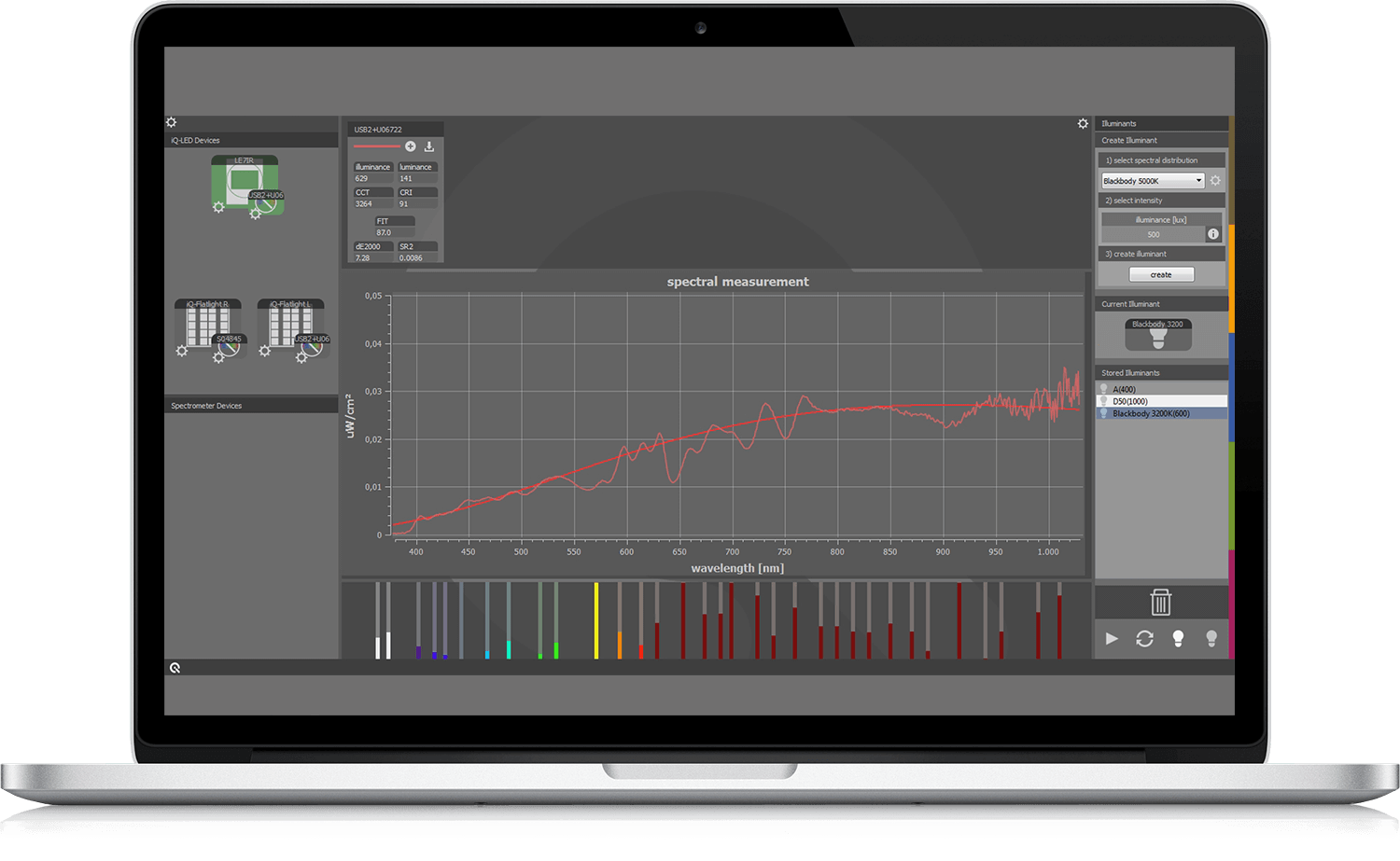

iQ-LED technology uses a NIST traceable calibrated spectrometer and iQ-LED control software to calibrate and correctly generate the spectra. Once correctly calibrated, the illuminant can be stored on the device and used without a PC. Up to 44 illuminants and one sequence can be stored on the device.

Please see the article here for detailed information on iQ-LED technology.

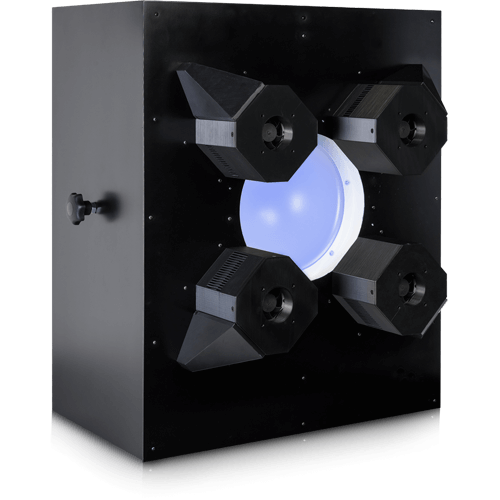

Combining iQ-LED with integrating spheres

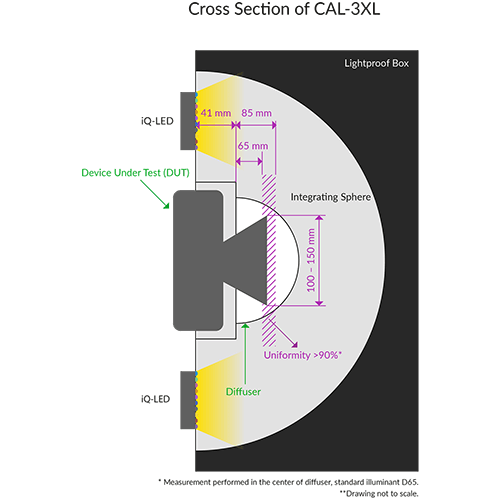

The light emitted from the high-power LEDs per element needs to be mixed before they reach the DUT. Using integrating spheres in combination with special selected diffusers has proved to be an ideal option to achieve optimal mixing. These spheres are uniquely designed using a non-reflecting special diffuser filter to ensure even light distribution on the measuring plane. Multiple iQ-LED modules can operate within one light source all of which, are controlled from the UI software or API.

A full camera calibration can then be completed in a matter of seconds, due to the short response time of the LEDs, as long as the image processing and transfer of the camera is fast enough. The combination of these features makes CAL technology ideal for production line integration.

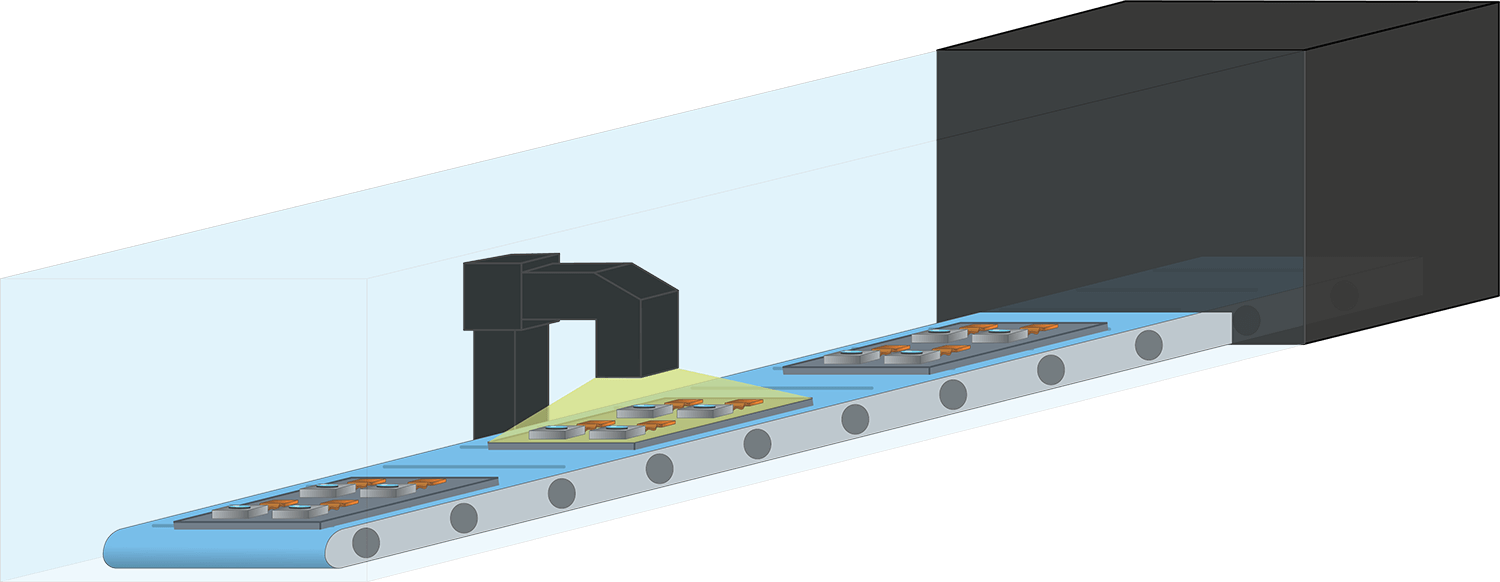

Production line integration

We offer a series of CAL devices in various shapes and sizes to ensure that we cover the requirements of different production lines. We equip the devices with special advanced production line features including temperature sensors, self-testing at startup, and an operation hour counter for smoother integration. Depending on the setup, it’s possible to calibrate multiple camera modules at the same time using the CAL devices.

Each device uses a NIST traceable calibrated spectrometer and iQ-LED control software to calibrate and correctly generate the spectra. Once correctly calibrated, the illuminant can be stored on the device and used without a PC. Up to 44 illuminants and one sequence can be stored on the device, making the CAL devices even more practical for production line use.

Production line partnerships

To further strengthen our CAL technology on the production line, we often supply our CAL products to other production line suppliers looking to integrate the benefits of iQ-LED with their devices. Working with these suppliers allows us to offer other advanced solutions for production line camera calibration and characterization.

The CAL devices

CAL1

The CAL1 is a 0.3 m integrating sphere that uses iQ-LED technology to illuminate a 70 mm opening for camera characterization and calibration. A non-reflective diffuser filter with improved Lambertian characteristics on the sphere opening ensures illumination uniformity.

CAL2

This ultra-compact light source is based on iQ-LED technology and can adapt to many different areas of measurement. Its edge box design makes it particularly suited for calibrating cameras on a production line. A non-reflective diffuser filter with improved Lambertian characteristics on the box opening ensures illumination uniformity.

CAL3

The CAL3 is a 0.3 m integrating sphere that uses iQ-LED technology to illuminate a 38 mm concave curved opening. The curved opening, as opposed to flat (CAL1), is more suited for wide-angle cameras. A bowl-shaped non-reflective diffuser filter on the sphere opening ensures illumination uniformity.

CAL3-XL

The CAL3-XL is an iQ-LED integrating sphere with a circular 196 mm opening and a bowl-shaped diffuser for illumination uniformity. It is ideal for camera calibration and testing of large cameras with wide-angles.

See the individual product pages for detailed information on each CAL device.

Want to learn more about production line image quality testing?

Contact us to set up a training session with our engineers.