Spectral Sensitivity

TechnologyIntroduction

Camera sensitivity at its most broad describes how sensitive a camera is to a particular light level. It is one of the essential camera performance indicators to measure as it provides insight into how the camera will react when capturing images at various light levels. Sensitivity itself can be broken down into subcategories, including ISO sensitivity and spectral sensitivity.

ISO sensitivity describes the overall sensitivity of a camera in a single value. This value is determined using an exposure index outlined in ISO 12232. Many of these ISO values (settings) are available as pre-sets on a camera. Thus, you can set a camera to a particular ISO setting depending on the surrounding illumination.

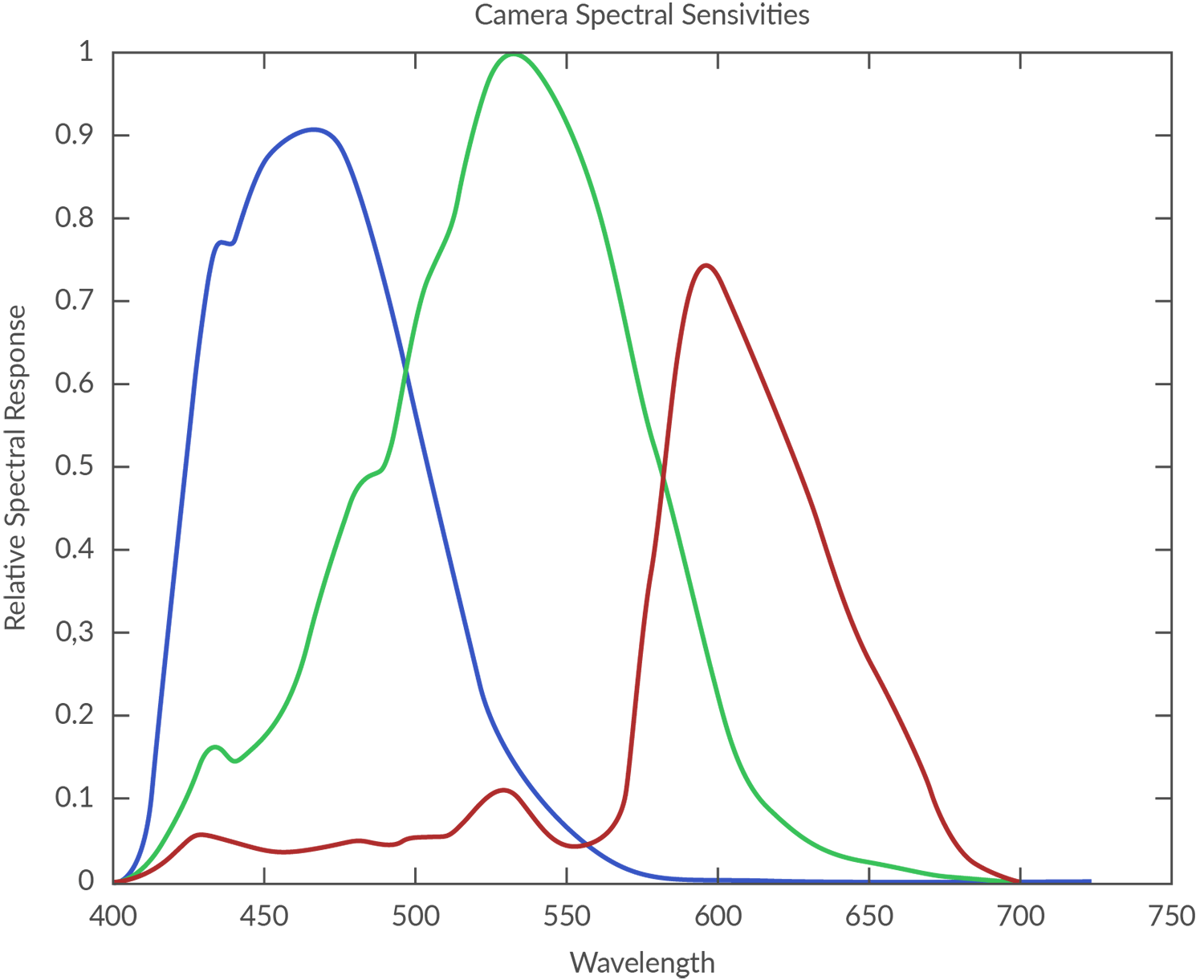

Spectral sensitivity describes how sensitive a camera is to each wavelength in the visible spectrum. This type of sensitivity is depicted using light curves instead of single values and can thus be expressed in various forms, e.g., microwatts, square meters, etc.

This article will mainly focus on the importance of spectral sensitivity and the technology behind the various tools used to measure it.

The importance of measuring spectral sensitivity

Camera systems react differently depending on the light. This reaction is known as the spectral response of the camera. Measuring the spectral sensitivity will provide a definitive idea of the various spectral responses to different light spectra.

The camera sensor reacts to a multitude of wavelengths that the human eye cannot perceive. As a result, camera settings must be manufactured to ensure a proper spectral response depending on the light environment.

During the manufacturing process of the camera sensor, it’s vital to test the spectral sensitivity so that adjustments are made before release.

Measuring spectral sensitivity

There are various methods for measuring spectral sensitivity, with the traditional one being the use of a monochromator. However, different technologies and measurement devices have been developed to address particular requirements within the field.

Our R&D team continues to research and advance the field by offering various solutions for spectral sensitivity measurements in different test environments.

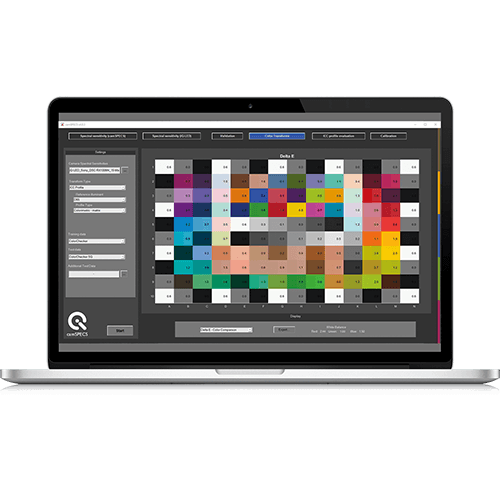

camSPECS

The traditional method for measuring spectral sensitivity is to use a monochromator. These devices will provide the most comprehensive overview of a camera’s spectral sensitivities, but they require extensive knowledge and a time-consuming process to run effectively. With that in mind, we began developing the camSPECS, a more cost-effective solution for spectral sensitivity measurements.

camSPECS combines a unique hardware design with evaluation software to create faster and more convenient spectral sensitivity measurements. The hardware mounts all interference filters onto one plane or test chart (as opposed to separate interference filters commonly seen with monochromators). The “test chart” is mounted onto the light source (halogen). In addition, the camSPECS has fixed bandwidths to ensure power output for the interference filters is equal and does not exceed the dynamic range of the camera. Set bandwidths make the camSPECS a much more straightforward option for measuring spectral sensitivities.

The software further increases the camSPECS’s convenience by calculating the spectral sensitivities of the images and calibration data of the filters as a direct measurement (similar to a monochromator).

The main spectral sensitivity application of the camSPECS is the calculation of color correction matrices (CCMs) with the CIECAM16 model and the export of ICC and Adobe ACR profiles with 2D- and 3D-MLUT rendering. In addition, you can calculate individual CCMs using the spectral radiance of natural objects, which we have gathered together in an in-situ database.

iQ-LED and in-situ

Both camSPECS and monochromators rely on a halogen light source, which, while sufficient, is not a long-lasting light source. Therefore, frequent replacement of the light can disrupt a workflow, especially with daily spectral sensitivity measurements. A solution to this issue is iQ-LED illumination technology. This technology can generate custom spectra, making it highly versatile while also lasting 10,000 hours before degradation (please see our iQ-LED technology page for more details).

Measuring spectral sensitivities with iQ-LED devices (e.g., CAL) can be tricky because they have varying bandwidths. However, using an iQ-LED device with known spectral measurements, such as from the in-situ database, creates the possibility of measuring spectral sensitivities with iQ-LED.

This solution is especially beneficial for production lines. With our CAL devices (see production line technology page for more details), integration of iQ-LED technology is a relatively simple process that will allow the measurement of spectral sensitivities of multiple camera modules on a production line at the same time.

LE7 and camSPECS plate

The camSPECS plate (TE292) is another solution for measuring spectral sensitivities with a stable light source. Essentially, the plate is the same as the front plate of the complete camSPECS device, but as a standalone “test chart,” must be combined with a broadband uniform illumination device, such as the LE7 lightbox. The LE7 uses iQ-LED technology and known spectral measurements to create a stable lighting environment for spectral sensitivity measurements.

Conclusion

Understanding the various spectral responses to different light spectra of a camera system is essential for overall performance evaluation. Thus, it’s crucial to test the spectral sensitivities of a camera system. The traditional method of using a monochromator is still sufficient but requires extensive knowledge and time to operate. As a result, many alternative technologies and devices have been developed to make spectral sensitivity measurements faster and more convenient.

Want to learn more about spectral sensitivity?

Contact us to set up a training session with our engineers.