Color Accuracy

Image Quality FactorsIntroduction

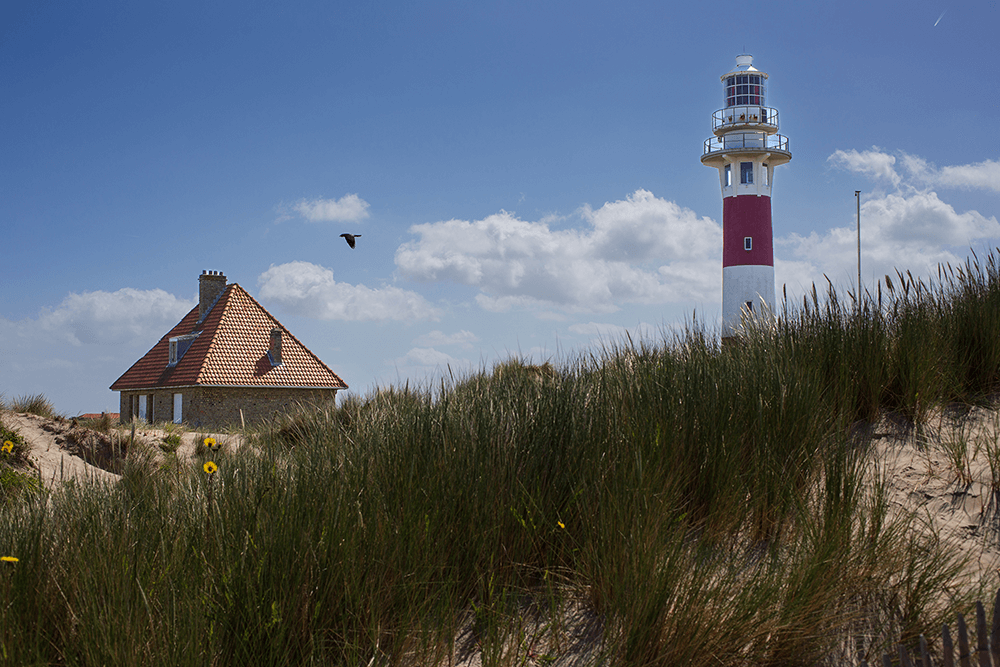

Color is one of the most crucial factors in image quality, impacting an image's overall perception and accuracy. In digital photography, how cameras capture and process color can significantly alter how the viewer perceives the scene. This fact is true for almost any industry, such as professional photographers attempting to accurately depict a scene or an autonomous vehicle differentiating the colors of road signs.

As a result, the color reproduction accuracy of camera systems must be thoroughly assessed and optimized to ensure high image quality performance.

The importance of color in image quality

When color imaging was first invented, it paved the way for humans to convey a more authentic representation of the world around them. This impact cannot be overstated, as proper color reproduction has become vital for every industry that relies on imaging. Take, for example, medical imaging, where color variations can indicate different disease conditions, or autonomous vehicles that need to interpret the color of painted lines in a construction zone. Without accurate color reproduction, we risk more than just faulty photos in today's technology-driven world.

Several factors contribute to the color performance of an imaging system, including the camera sensor, image processing algorithms, and display technologies. An error in any one of these aspects can create inaccurate colors. With that in mind, it is crucial to understand and test the color reproduction of these camera systems to ensure the highest level of image quality.

What are the key aspects of color?

Color scientists use various methods to describe the nature of color in imaging systems. These methods help us assess how accurate a particular system is when reproducing color profiles.

ICC Profiles

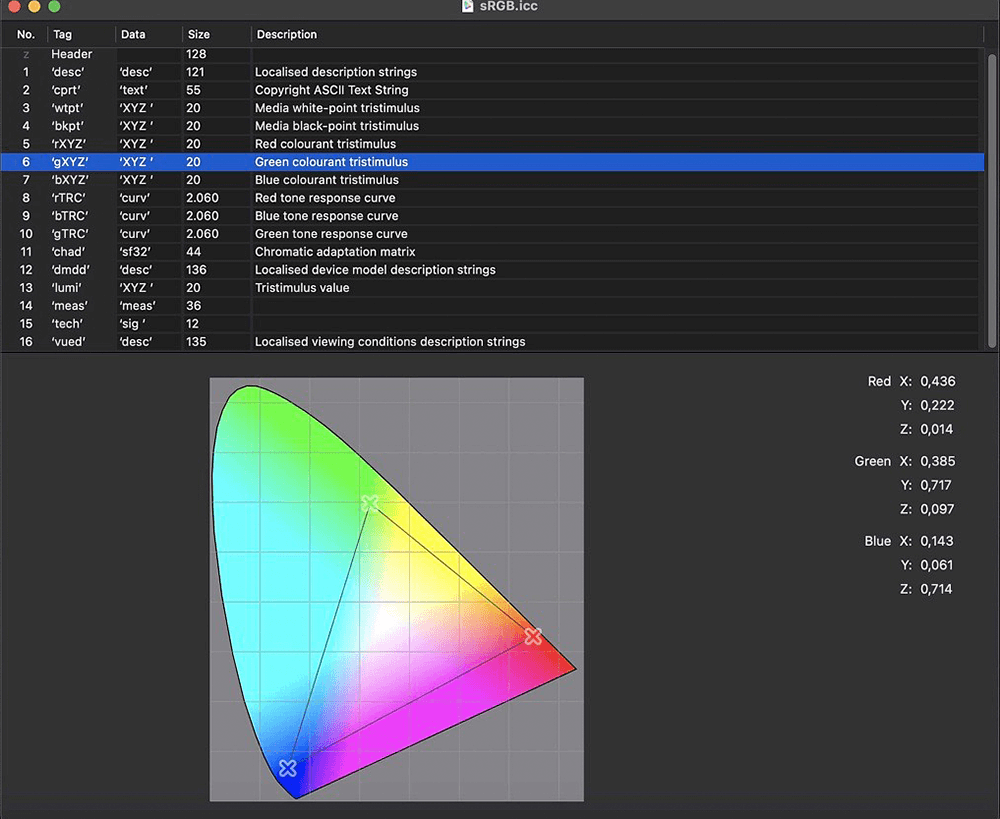

ICC (International Color Consortium) profiles are standardized files describing an imaging device's color characteristics. They are generated during the beginning stages of the calibration process and utilized for all subsequent devices going through calibration and characterization. In addition, many ICC profiles are widely available and can be downloaded for calibration. ICC profiles are used for both hardware and software color calibration and are crucial for maintaining color accuracy across multiple devices, e.g., cameras, monitors, and printers.

Color Matrices

A color matrix is a mathematical transformation applied during image processing to convert the raw color data captured by a camera sensor into a standardized color space, such as sRGB. This transformation is necessary because camera sensors capture light in a way that differs from how humans perceive color. The color matrix corrects these differences to reproduce more accurate colors. Determining color matrices is critical for ensuring that the output image closely matches the original scene.

Color Gamut

Color gamut refers to the range of colors a specific imaging system can generate, e.g., a display or a printing system. Different devices often have different color gamut, but to ensure accuracy, all of these devices should be able to reproduce a comprehensive and accurate range of colors to ensure high image quality. Standard color encodings include sRGB, Adobe RGB, and ProPhoto RGB, each offering different gamuts, meaning different extents of color coverage. A wider gamut allows for more saturated colors but requires proper color calibration and management to ensure consistency across various imaging devices.

RGB vs. CMYK

RGB (Red, Green, Blue) and CMYK (Cyan, Magenta, Yellow, Black) represent different color models used in imaging systems. RGB is an additive color model mostly used in camera systems and displays. It combines various intensities of red, green, and blue light to recreate the scene's colors. CMYK is a subtractive color model used primarily by printers to account for a (typical) white background of the printing paper. It combines cyan, magenta, yellow, and black ink to produce colors on a printout. Understanding the differences between RGB and CMYK is essential to ensure better color calibration and, ultimately, higher color accuracy in digital and printed formats.

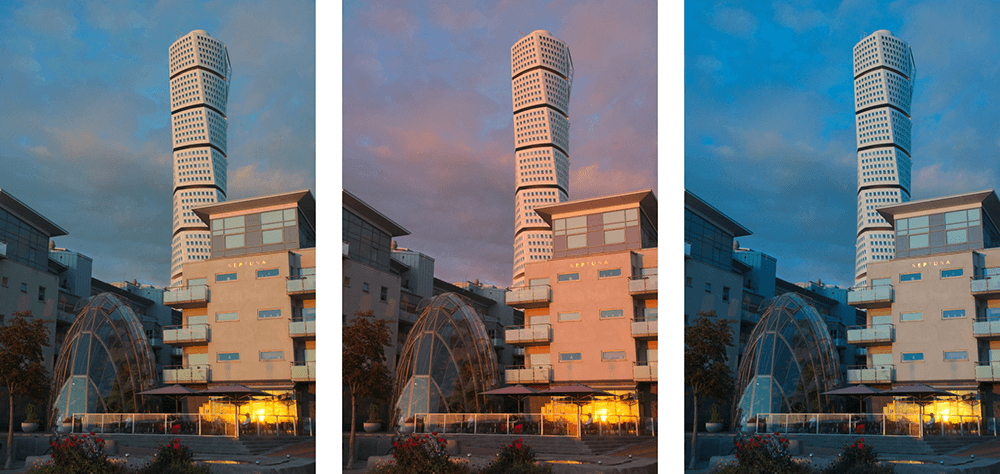

White Balance

The white balance function of a digital camera ensures the objects in the image field are captured with colors in correlation to the light source. In other words, we want our imaging systems to ensure that the white and the greys in the images appear neutral without any color cast. White light sources are not always the same and can have different color temperatures (e.g., the sun, while the same light source varies depending on the time of day). Without proper white balance, these images would appear with an unwanted color tint. Typically, the camera automatically adjusts the white balance depending on the type of light source. Proper white balance is essential for avoiding color inaccuracies, especially in mixed lighting conditions or scenes with complex lighting.

Color calibration background

Color calibration is critical to ensure an imaging system can accurately reproduce colors according to a particular color model (RGB or CMYK). Calibration aligns the color reproduction of an imaging device with predefined specifications to ensure consistency and accuracy across devices and lighting environments. Images may have false color shifts without proper color calibration, leading to poor image quality.

Color calibration is essential for companies that produce imaging and sensor systems. For example, a photograph edited on one monitor should appear identical when viewed on another. That same is true for autonomous driving cameras and sensors. If they do not interpret colors the exact same way to make the proper adjustments, we create unsafe driving conditions. We can ensure that colors will be reproduced accurately on multiple devices only with proper calibration.

International standards

International guidelines such as ISO standards are recommended to ensure consistent image quality measurements across devices and lab setups. The ISO 17321-1 standard focuses on color characterization and calibration of digital still cameras by providing test methods for assessing how accurately a camera can reproduce colors. This is the standard that we closely follow when testing in our iQ-Lab.

Color characterization methods

Obtaining the spectral sensitivities

The most accurate option for color characterization is obtaining the spectral sensitivities of the camera or imaging device. Spectral sensitivities are ideal for generating an ICC profile or color correction matrix (CCM), making it the most vital step for camera color characterization and calibration. After correcting the colors, you can determine the remaining color inaccuracies of your camera module since it is impossible for most cameras to correct all colors to the full extent.

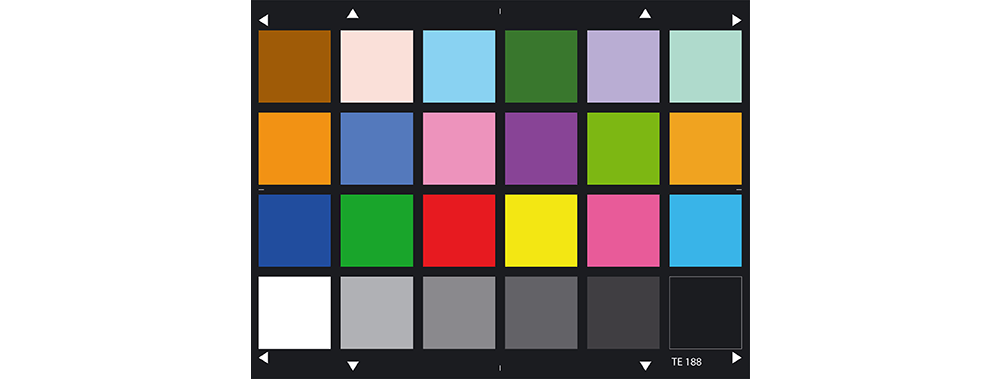

Method 1: Color Test Charts

Color test charts, such as the ColorChecker, are commonly used tools for assessing the color accuracy of cameras. These charts contain patches of standardized colors that cover a wide range of the visible spectrum. A color profile or correction matrix can be generated by capturing images of the chart and comparing them to the reference values provided by the manufacturer. That way, deviations are minimized.

Method 2: A test chart using narrow-band interference filters

The standard method to obtain the spectral sensitivities is to use a monochromator. However, monochromators are often complicated tools that require expertise to function correctly. We have developed a test chart using narrow-band interference filters to improve this issue. These are better suited for measuring the spectral sensitivities of camera systems and are easier to handle than a monochromator. We incorporate this unique "test chart" throughout our camSPECS product line.

Once a single image of the interference filter chart is captured, you can load it into the camSPECS software to automatically analyze it. Once analyzed, the software will show you the spectral sensitivities of your camera. This method provides the basis for increased accuracy for camera color characterization.

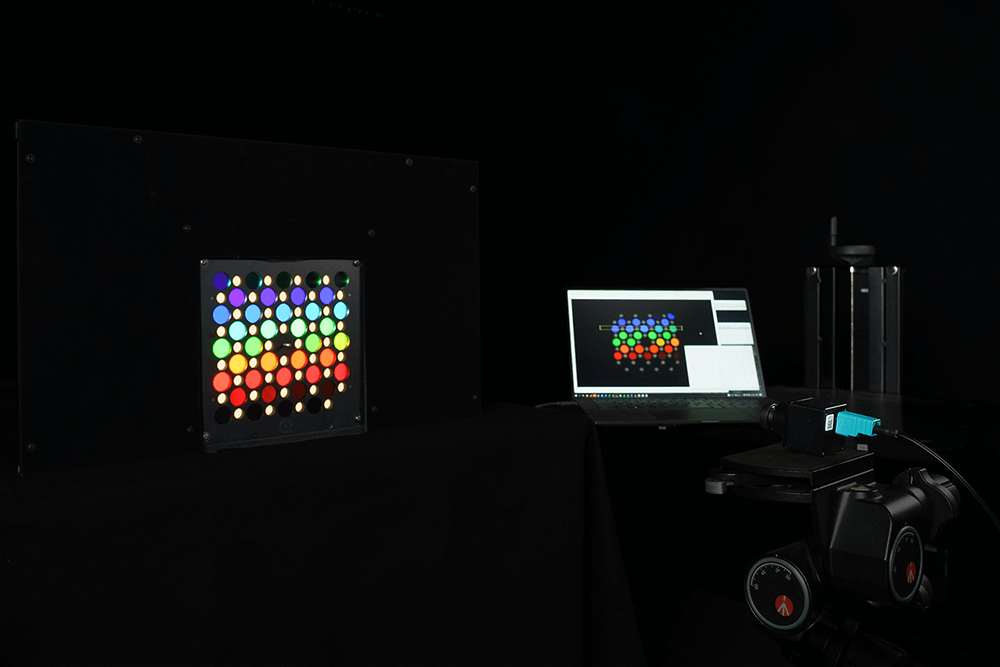

Method 3: Using a spectrally tunable light source

A spectrally tunable light source can generate custom spectra, making it the most versatile method for obtaining spectral sensitivities and generating color profiles. Our iQ-LED devices are spectrally tunable and have 41 high-power SMD LEDs separated into 20 channels. We capture an image of each illuminated channel when using the devices to measure spectral sensitivities.

How we measure color in the iQ-Lab

In our iQ-Lab in Kerpen, we use a combination of the methods described above depending on the device's requirements under test. You will need a proper lab setup optimized for your testing process. See our article on how to build an image quality lab for more details.

We could use a color chart to create a color profile by capturing images of the chart under various lighting conditions. When using this "chart-based" method, we recommend using a spectrally tunable light source, such as the iQ-Flatlights, as they can generate all the essential spectra to create a color profile.

When utilizing camSPECS, we capture a single image of the interference filter plate and load it into the camSPECS software to automatically analyze and convert it. Once analyzed, the software will show you the spectral sensitivities of your camera and allow you to create a CCM or an ICC profile.

Images captured using an iQ-LED device are also evaluated using the camSPECS software. Due to the limited number of iQ-LED channels, you must use a spectral estimation method to get to the spectral sensitivities. Once complete, you can import all the images into the software. From there, you need to define the spectral distribution of each channel, which you can determine in the iQ-LED software. Then, your spectral sensitivities are automatically calculated, and a CCM can be generated.

Production line color calibration

Many imaging applications produce camera modules on a production line. As a result, methods for calibration on a production line are crucial to improve quality and efficiency. Our iQ-LED devices can be integrated into a production line with an established method to generate CCMs or ICC profiles, allowing you to perform multiple calibrations simultaneously. For more information on the best practices for production line color calibration and characterization, please see this conference paper from Eric Walowit.

Conclusion

Color is a fundamental factor of image quality, influencing how images are perceived and interpreted. Accurate color reproduction ensures images are visually appealing and true to life. By understanding the different aspects of color, such as color matrices and gamuts, ICC profiles, and white balance, image quality engineers can optimize the color performance of their imaging systems.

Color calibration, meanwhile, plays a pivotal role in maintaining color accuracy, ensuring that devices reproduce colors consistently and according to standardized profiles. At Image Engineering, we provide a broad range of tools for characterizing color performance and performing color calibrations for almost any type of imaging system.

We have come a long way in color imaging from the days of black and white. In fact, color in imaging has become so vital to our everyday life that yearly conferences such as the Color in Imaging Conference (put on by IS&T) ensure engineers and scientists are up to date on the latest characterization and calibration methods. Even still, we often take color in imaging for granted, as it's hard to imagine a world without it. Nonetheless, color reproduction by camera systems is frequently volatile and requires strong engineering and an understanding of color science to ensure accurate color reproduction.