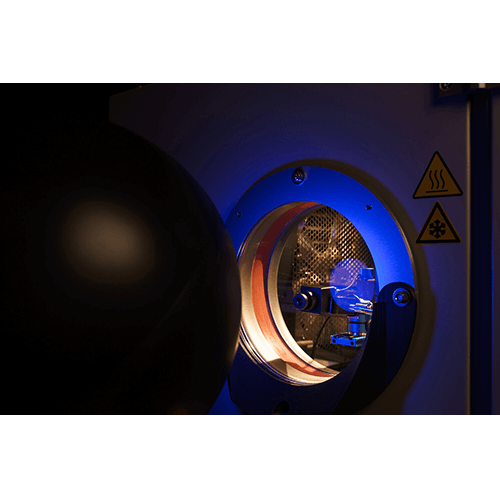

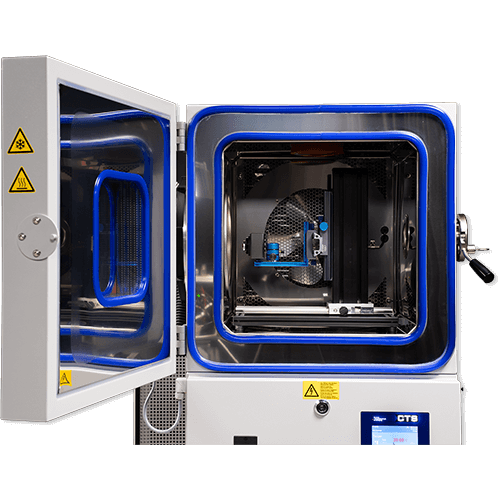

Controlling the temperature

Temperature-controlled testing in a test lab

One of the more significant problems facing camera system developers is ensuring that their systems function reliably in changing weather environments. This issue is particularly relevant in the automotive and security camera industries that depend on various camera systems to keep consumers and the general public safer.

Our latest blog article details the challenges and solutions of image quality testing in fluctuating temperature environments, including how to test cameras in a temperature-controlled test lab environment.

iQ-Climate Chamber solution

A temperature-controlled solution for camera performance testing

The iQ-Climate Chamber solution can generate various temperature ranges for camera performance testing. It is currently the only solution on the market for testing a camera system in a temperature-controlled environment.

The solution has a test range of -30° to 120° C, allowing you to create almost any temperature scenario within the confines of your test lab. It has quickly become one of our most popular testing solutions, especially for companies evaluating how their camera systems adapt and perform to a constantly changing environment, such as those from the automotive and security industries.

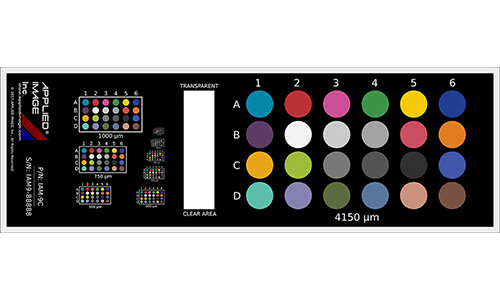

New test chart: IAM-9C

NIST traceable color transmission calibration chart

Our latest chart, IAM-9C, uses 24 color patches in nine different sizes on a black background for color reproduction testing. Patch size ranges from 0.150 to 4.150 mm in diameter, with the largest patches being NIST traceable calibrated. The iQ-Analyzer-X image evaluation software supports this chart.

AutoSens Brussels 2023

19-21 September 2023 in Brussels, Belgium

Will you be joining us in Brussels this September? We will again participate in one of our favorite events of the year. AutoSens will take place from the 19th – 21st at the Autoworld Museum in Brussels. We will showcase some of our latest advancements in automotive image quality testing including:

- GEOCAL-IR (prototype): An NIR device for geometric camera calibration in the NIR range.

- Arcturus (prototype): Based on our Vega light source with a smaller output window and as much as 20x the intensity of Vega.

- KORK (prototype): A new device for aligning radar and visual cameras.

We will also presenting our latest software including for contrast transfer accuracy (CTA) measurements. We look forward to seeing you there!

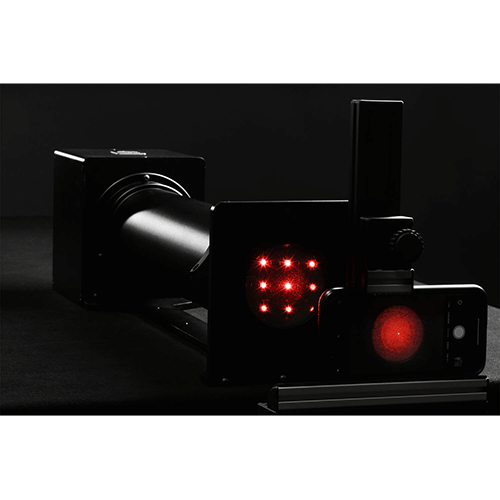

GEOCAL-IR

Geometric camera calibration in the near-infrared range

GEOCAL is a compact solution that maps distortion using a beam-expanded laser combined with a diffractive optical element (DOE). This solution eliminates the need for extensive floor space, external light sources, relay lenses, etc., while still providing the ability to measure all lens distortion's intrinsic and extrinsic parameters.

The IR version expands the laser diode wavelength range to 935 nm, allowing you to perform geometric camera calibrations in the NIR region.

ISO 9001:2015 certification

We are proud to be officially certified

Customer satisfaction is a top priority for us at Image Engineering GmbH & Co. KG. Our quality management system is focused on continuously developing and improving our processes to ensure the highest level of customer satisfaction. Image Engineering has been ISO 9001 certified since June 29, 2023.