What is flicker?

Light flicker is defined as a change to the brightness or intensity of a light source. This change can be intentional, e.g., flashing light from an emergency vehicle or unintentional, e.g., fluctuations in the voltage of power lines. As a result of its changing nature, flicker can be difficult to quantify in a test setting. However, with the continuing advancement of cameras and sensors in certain industries such as automotive (ADAS in particular) and security, it is becoming more imperative to recreate and test flicker in a lab setting.

How does flicker occur?

Flicker often occurs from LED equipment due to the particular construction of the light source. It can also arise from the natural surroundings such as the sun flickering in between different objects while driving. Technically speaking, flicker is a temporal light modulation (TLM) that can drastically alter the dynamic of the scene and affect the performance of a camera or sensor.

The importance of testing flicker

Light flicker can affect almost all industries that rely on cameras and sensors, but it’s most evident in the automotive and security industries. Flicker is a common occurrence in these industries because the surrounding environments are constantly changing and producing a broad range of lighting situations. The camera and sensor systems, however, must be able to adapt to the changing environment to ensure high performance and safety. For example, an ADAS system must always react correctly even with an inconsistent light flicker to avoid a dangerous driving situation.

Industry engineers understand the importance of flicker but are finding it difficult to reliably test different flicker situations in the test lab. As a result, our engineers at Image Engineering have developed and are developing different hardware and software solutions that can accurately reproduce light flicker in a test lab setting.

Tools for testing flicker

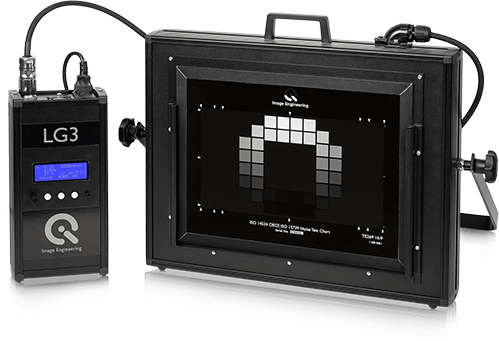

The LG3 illumination box is the first light box on the market with flicker capabilities. Based on iQ-LED technology, the LG3 greatly expands the test areas for dynamic range measurements with the ability to illuminate a high contrast test target with over 150,000 lx. It is used with transparent test charts such as the TE269 test chart.

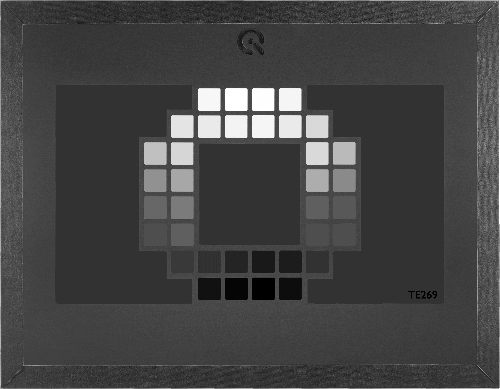

The TE269 test chart not only follows ISO 14524 and ISO 15739 but also IEC 62676-5, the first international standard regarding the measurement methods and descriptions of security and surveillance cameras. The chart is suited for high dynamic range measurements of 1,000,000:1 / 120 dB.

The flicker mode has a range of 10 to 500 Hz and variable duty cycle meaning it can simulate variable flicker frequencies i.e., those of traffic and street lights. There is also a mode of 32 kHz/128 kHz and variable duty cycle.

With these advanced capabilities, the LG3 has proven to be a solution for accurately recreating different flicker situations in a test lab environment.

One of the most popular test charts that we recommend to use with the LG3 is the TE269 OECF 36 patch test chart. This test chart has 36 grey patches for measuring the OECF of a camera. The TE269 test chart not only follows ISO 14524 and ISO 15739 but also IEC 62676-5, the first international standard regarding the measurement methods and descriptions of security and surveillance cameras. The chart is suited for high dynamic range measurements of 1,000,000:1 / 120 dB.

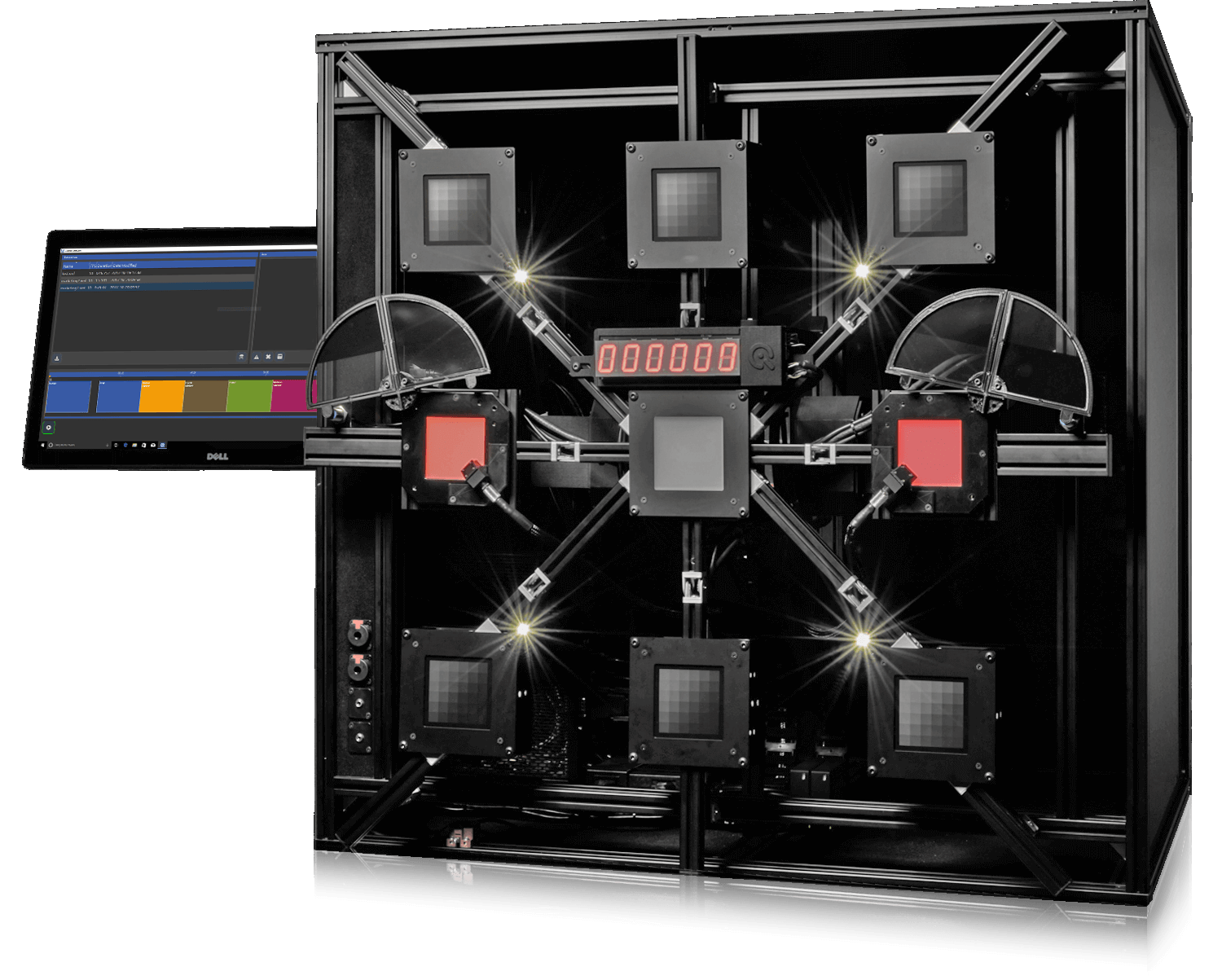

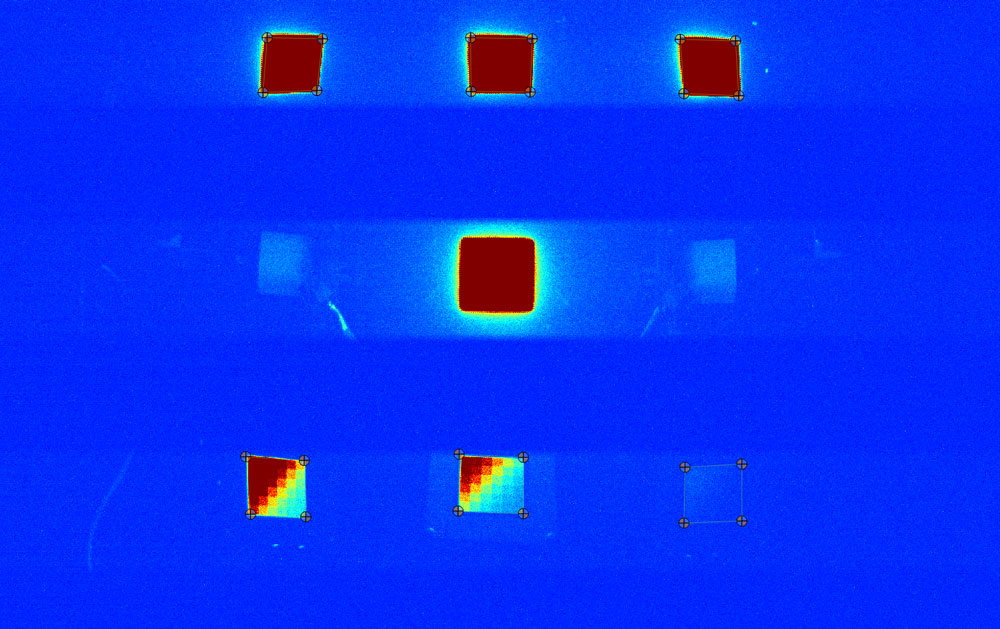

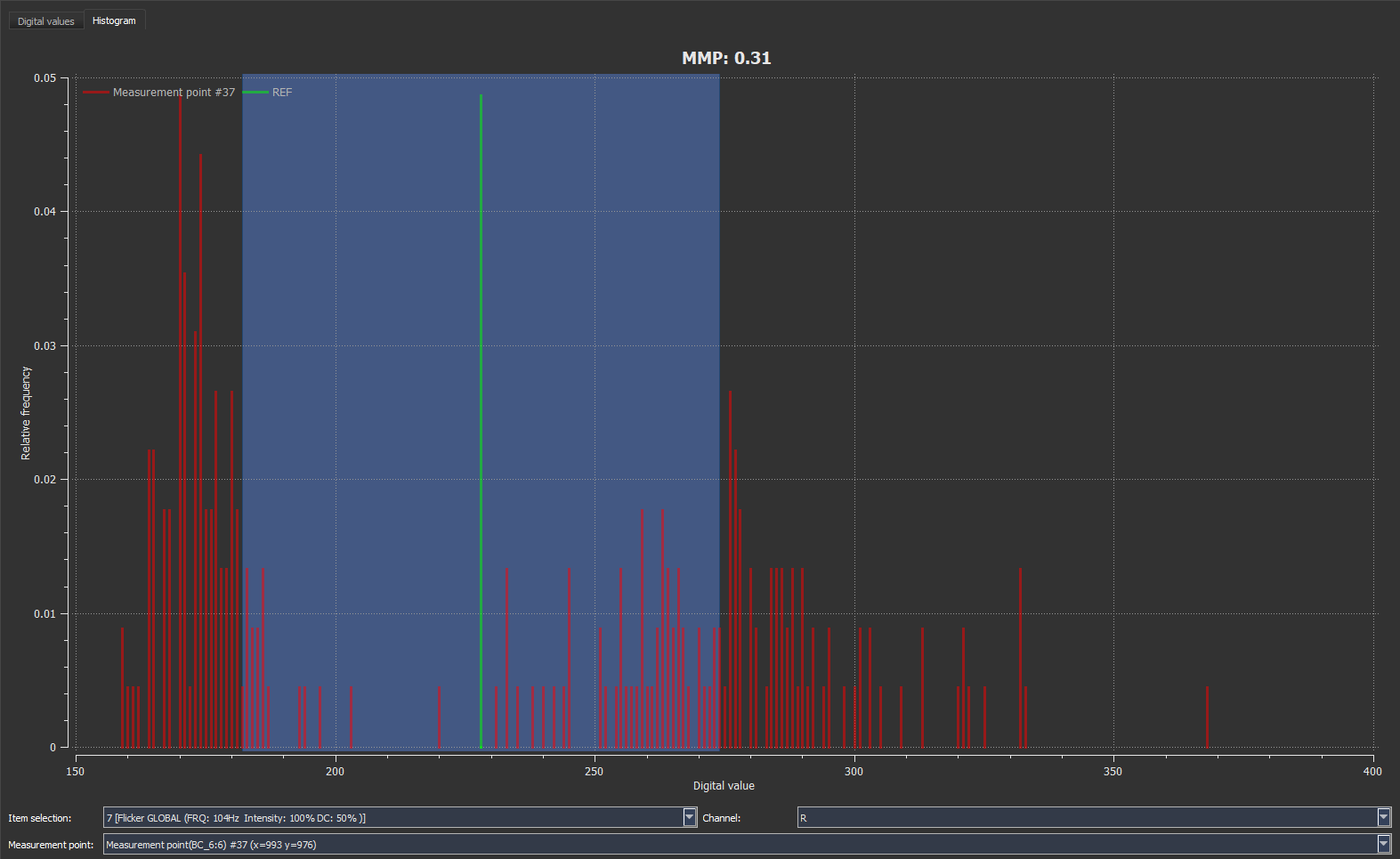

Another product for testing flicker is the Dynamic Test Stand (DTS) -- an ADAS testing solution for various KPI’s (Key Performance Indicators) including modulated light mitigation probability (MMP) or flicker (as it is commonly known). ADAS cameras and sensors must be able to perform at the highest level in all types of different conditions to avoid any dangerous driving situations.

The flicker mode of the DTS uses six contrast boxes based on LG3 technology to check the camera systems response to modulated light across a dynamic range of 120 dB. Overall the DTS has 216 unique luminance’s that can be tested. There are also four single LED lights for measuring the response of the system to local flicker.

Apart from the hardware, the DTS also has its own analysis software for analyzing the results once the cameras or sensor has gone through the testing. The analysis will provide you with details on where the system must be improved. The MMP evaluation module is currently the only available analysis software for flicker on the market.

ADAS camera and sensor systems must perform at a high level at all times, thus the testing and analysis of these systems must be rigorous to ensure safety. Flicker is just one of the many KPI’s that should be tested for ADAS systems.

Conclusion

Flicker is an inconsistent change to the brightness or intensity of a light source and often has a negative impact on the performance of a camera and sensor system. In general, systems from the automotive (ADAS) and security industries frequently experience performance problems due to the inconsistencies of their surrounding environments.

When an ADAS camera, for example, encounters performance problems due to flicker, we will experience an unsafe driving situation. As a result, these types of systems must be thoroughly tested and evaluated in a test lab before they made available to the public.

Until recently, it was very difficult to accurately simulate flicker in a test lab setting. Currently, however, our engineers have developed two different solutions including the LG3 lightbox for transparent test chart illumination, and the DTS for testing ADAS camera systems. Each device has a range of 10 to 500 Hz and variable duty cycle to simulate variable flicker frequencies.

For more technical details, please see the respective product page on our website. You can also contact us if you have further inquiries about testing flicker or any other image quality-related test questions.